Wash Alert Parameters

To meet regulations and maintain the quality of the milk and milking devices, the milking system must be appropriately washed and sanitized following each use.

To achieve the required wash standards that define a proper wash, the wash procedure must meet the following three conditions:

-

Sufficient washing time – includes all or some of the following cycles:

-

Pre-wash rinse – removes milk residues,

-

Detergent wash – disinfects the milking system,

-

Acid wash – removes milk and water mineral deposits (soil) from the inner surfaces of the milking system.

-

Sufficient water temperature - wash solution temperature is crucial for proper cleaning of milking systems according the detergent/acid used, as follows:

-

Pre-wash rinse – typically requires lukewarm water to prevent milk proteins solidifying onto inner surfaces of the milking system.

-

Detergent wash – requires higher temperatures, as per manufacturer instructions.

-

Acid wash – water and mineral deposits become more soluble with higher wash temperatures.

-

Sufficient detergent concentration – detergent concentration is essential for proper wash. Sufficient concentration is measured through solution conductivity.

Afimilk's wash monitoring system measures the wash cycle temperature, wash time, and wash solution electrical conductivity to determine if a proper wash was achieved in each milking point.

In principle the system measures the wash quality in comparison to the following thresholds:

-

Wash temperature – the minimal temperature for effectively activating the detergent, as defined by the chemical manufacturer,

-

Wash Time – the time during which the water temperature is above the minimal threshold is considered a proper wash. This time is defined as the minimal time for the wash cycle.

-

Conductivity – the Afimilk MPC Milk Meters incorporate an internal threshold for identifying the chemicals running through it (as opposed to clean water). Conductivity time is therefore the time during which the milk meter identifies the wash chemical.

Alert parameters are used to set the minimum wash requirements. When these thresholds are not achieved, an alert is triggered. The thresholds can be adjusted to make the system either more or less sensitive to variations in wash time, temperatures and chemical concentration.

Warning: Consult with Application support before making any adjustments to the parameters.

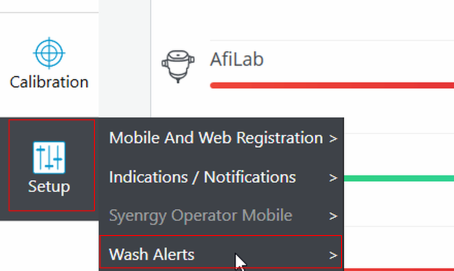

To access the wash alerts setup

-

In AfiControl, click Setup, then click Wash Alerts.

-

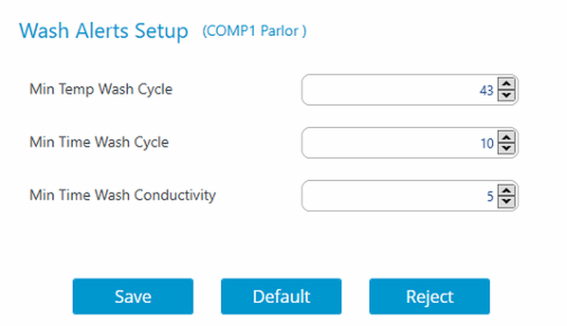

Set the parameters as follows:

|

Data |

Description: |

|---|---|

|

Min Temp Wash Cycle |

Set the minimum lowest temperature that must be achieved during the wash. |

|

Min Time Wash Cycle |

Sets the minimum amount of time the minimum wash temperature must be achieved. |

|

Min Time Wash Conductivity |

Sets the minimum amount of time for chemicals to be detected by the system. |

Alerts are activated for deviations from the expected procedure. Use the alerts to determine if the faults are at a system level or associated to specific wash points (milk meters).

Open the Wash Report to view if, where, and why the system failed to wash properly.