Wash Alerts Report

The upper table presents the wash points (milk meters) that failed to accomplish proper wash targets.

Rouge - Indique qu’une panne s’est produite lors de la dernière session terminée.

Rouge - Indique qu’une panne s’est produite lors de la dernière session terminée.

Jaune - indique qu’une panne s’est produite lors de l’une des sessions précédentes, mais pas lors de la dernière session terminée.

Jaune - indique qu’une panne s’est produite lors de l’une des sessions précédentes, mais pas lors de la dernière session terminée.

Vert - Indique qu’il n’y a eu aucune panne.

Vert - Indique qu’il n’y a eu aucune panne.

|

Data |

Description |

|---|---|

|

Stall |

Affiche le numéro d’étable ; les étables présentant de récents dysfonctionnements sont répertoriés en premier dans ce tableau. |

|

Cycles |

Number of wash cycles identified. |

|

Temp. Time |

Indicates if the wash cycle achieved the minimum temperature requirements for the minimum amount of time defined in the system. Fault indicates the wash cycle did not maintain a sufficient temperature for enough time during the wash cycle. Persistent alerts may indicate an insufficient amount of hot water OR a local flow restriction at a specific point. |

|

Chemical time |

Indicates if the wash cycle achieved minimum required chemical concentration for the minimum amount of time. Fault indicates reduced chemical concentration in the wash solution OR late admission of the detergent. Consequently, exposure to active chemical in the system is insufficient. |

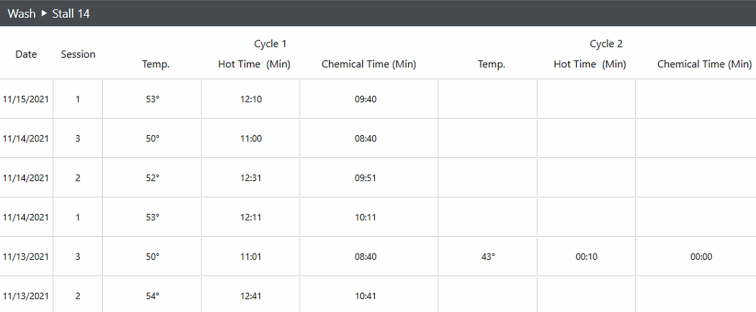

Lower detailed report: Click a row in the top table to display the wash measurements of the previous 6 sessions for the individual milking point. This report indicates the persistency of the fault.

The report displays two detected wash cycles (if only one cycle is detected, the measurements in the second cycle are empty).

The measured parameters displayed in the report are:

|

Data |

Description: |

|---|---|

|

Temp |

Displays the average temperature for the cycle. |

|

Hot Time (Min) |

Displays the amount of time during the cycle where temperatures exceeded the threshold. |

|

Chemical Time (Min) |

Displays the amount of time during the cycle where the presence of chemicals was detected (conductivity exceeded the threshold). |

The example above shows that during Session 3, two days ago, two wash cycles were identified for Stall 14 (commonly Detergent in the first and Acid in the second). In the first cycle a sufficient chemical concentration was only achieved for 8:40 (insufficient amount of time).

During the second cycle, the water temperature was not high enough for enough time, and no chemicals were detected during the cycle.

Wash faults that occur in one or more individual stalls suggests an issue with those stalls (such as blockage).

Wash faults with the entire parlor, or multiple stalls on the same side of the parlor, suggests an issue with the wash system.